Overview

Energy storage to buffer the intermittent supply of renewable energy is vital in decarbonisation of industry. Thermal energy storage (TES) is considered to be a significantly cheaper way to store energy (compared to, for example, electricity in pumped hydro or batteries) in cases where the energy is required in the form of heat. For example, HILT CRC project RP2.003 Green heat for industry identified that total lifetime cost per unit of heat (levelised cost) of heat in the form of molten salt storage TES is around 40% lower compared to using pumped hydro storage and conversion to heat.

One of the key challenges for heavy industry’s adoption of TES is integration. For very high temperature processes, such as calcination in alumina refining and heat supply to H2 direct reduced iron (DRI) processes, it is unclear how to best integrate TES, and whether its cost advantage over other options remains once integration costs are fully considered.

This project is enhancing our understanding of integrating TES into key heavy industry low-carbon transition processes by developing case studies, conducting technoeconomic analyses, and addressing feasibility challenges. Ultimately, it will identify a promising use-case for a pilot-scale TES demonstration.

This project is Phase 2 of RP2.009.

Project Details

Through systematic research and collaboration with industry and government, this project will deliver valuable resources, including policy maps, comparative analyses and practical recommendations. These will provide heavy industry with tools to align with and benefit from Australia’s low-carbon policies, and help industry leaders engage effectively with policymakers.

TES is a promising solution for decarbonising heavy industry by providing a cost-effective way to store and use renewable energy in the form of heat. Industries such as alumina refining, iron and steel production, and lime calcination require high-temperature heat (up to 1200°C) for various processes, making TES integration essential. However, while TES is widely recognised as more affordable than alternatives like batteries or hydrogen, integrating it into industrial processes – either retrofitted or in new builds – remains a significant challenge.

This work builds on phase 1 of the project, which identified a range of TES technologies suitable for industrial applications but highlighted the need to refine integration strategies. This new phase extends the scope to medium- and high-temperature use cases, addressing issues such as temperature compatibility, scale, cost-effectiveness, and infrastructure needs.

By conducting case studies, the project will explore TES integration scenarios for processes such as alumina calcination, bauxite digestion and hydrogen-based direct reduced iron. It will also assess practical challenges, such as material durability under extreme conditions and the feasibility of alternative methods for storing heat.

Through three parallel work plans focusing on alumina refining, iron and steelmaking, and cross-industry applications, the project aims to identify a viable use case for future pilot-scale demonstration. By addressing knowledge gaps and practical barriers, this research will pave the way for low-cost, renewable heat solutions, enabling industries to transition away from fossil fuels while maintaining operational efficiency.

HILT CRC Milestones

- 1.3 Low-carbon high-temperature alumina calcination

- 1.4 Low-carbon heat for the hydrometallurgical process component of alumina refining

- 2.2 Technology to accommodate use of multiple energy sources

Research Areas

- New technology to accommodate multiple energy sources and offer flexibility in switching between them

- New technologies for high temperature heat

Project Outcomes

Planned outcomes

- Process models showing feasible integration options for each case study.

- Integrated system models showing how a TES system can be operated over a year, including information relating to reliability of heat supply, sizing of components, and other practical challenges or risk factors.

- Value proposition analysis for each integration option, with comparison to alternative or hybrid options for renewable heat supply.

- Results and analysis from supporting experimental work in target areas.

- Assessment and planning towards a selected use case for future pilot-scale demonstration, including recommended objectives for design.

Adapting hot blast stoves for cost-effective long-duration thermal energy storage

High-temperature thermal energy storage (TES) could play a vital role in decarbonising industries that need heat, such as alumina calcination and hydrogen-based direct reduced iron (DRI) production.

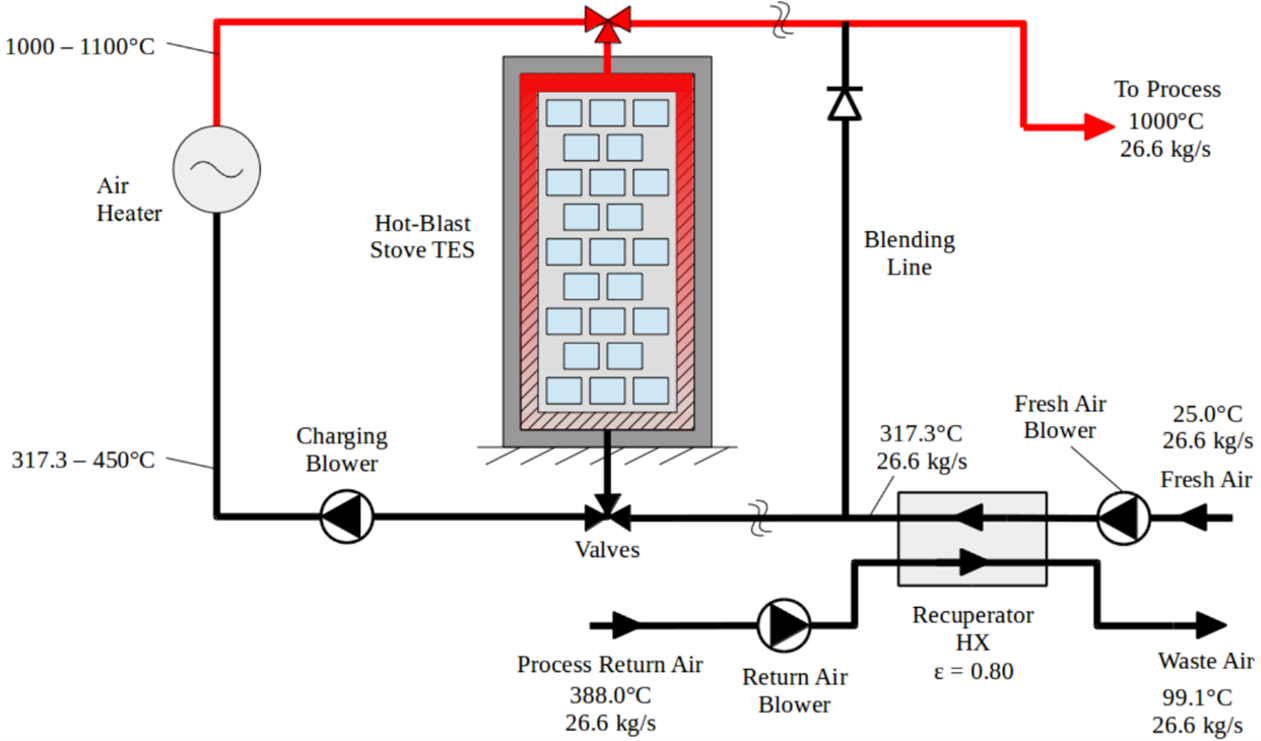

Recent modelling work, to be presented at SolarPACES 2025 this September, has focused on adapting existing hot blast stove (HBS) infrastructure – already used in steel plants – to function as long-duration TES and deliver hot air at around 1000°C. The research team modelled HBS performance using real brick geometries and validated the system using full-scale operational data.

While thermal energy utilisation in this modified system is constrained by temperature limits on structural materials, this can be improved by increasing storage capacity and heat exchange surface area. Insulation design is critical to minimise losses and maintaining laminar airflow is essential to keep pressure drops within acceptable limits.

The levelised cost of heat from this concept is found to be competitive – especially when the industrial process has some flexibility in timing, allowing the system to operate at less than full capacity. The modelling indicates that energy input costs dominate overall cost, rather than the TES system itself.

This work supports HILT CRC’s broader objective of identifying a viable use case for pilot-scale TES demonstration and helping heavy industry partners assess low-cost, low-emissions alternatives to fossil-fired heat.

Flow sheet showing how a hot blast stove TES system supplies 1000°C hot air to an alumina calcination process.

Project Benefits

Alumina refining

- Provides HILT CRC Partners with detailed information on how to integrate TES into alumina calcination processes.

- Identification of the best heat integration methods (in collaboration with the AlumiNEXT™ project).

- An understanding of which combination of TES, direct electrification and hydrogen combustion provides the most viable pathway to calcination decarbonisation.

- Insights into TES options for steam production in digestion and potential applications in bauxite beneficiation.

- Reliability and operational analysis based on long-term data

- Information on energy supply options (grid or dedicated solar/wind) and how these work in conjunction with TES (in collaboration with 007 Unlocking investment in energy infrastructure for net-zero industrial hubs).

- Evaluation of modular TES technologies, focusing on scalability and associated risks.

Iron and steel

- Identification of the most beneficial TES integration opportunities and evaluation of their feasibility and cost-effectiveness.

- Strategies for HILT CRC Partners for integrating TES into H2DRI processes.

- New knowledge on TES integration for process gas heating, a major energy requirement in DRI.

- New knowledge on TES applications for ore beneficiation processes such as magnetisation roasting, drying and pre-treatment.

Pilot-scale demonstration

- Support for Partners in moving towards a pilot-scale TES demonstration system.

- A preferred use case for detailed assessment to guide the design and implementation of the pilot system.