Overview

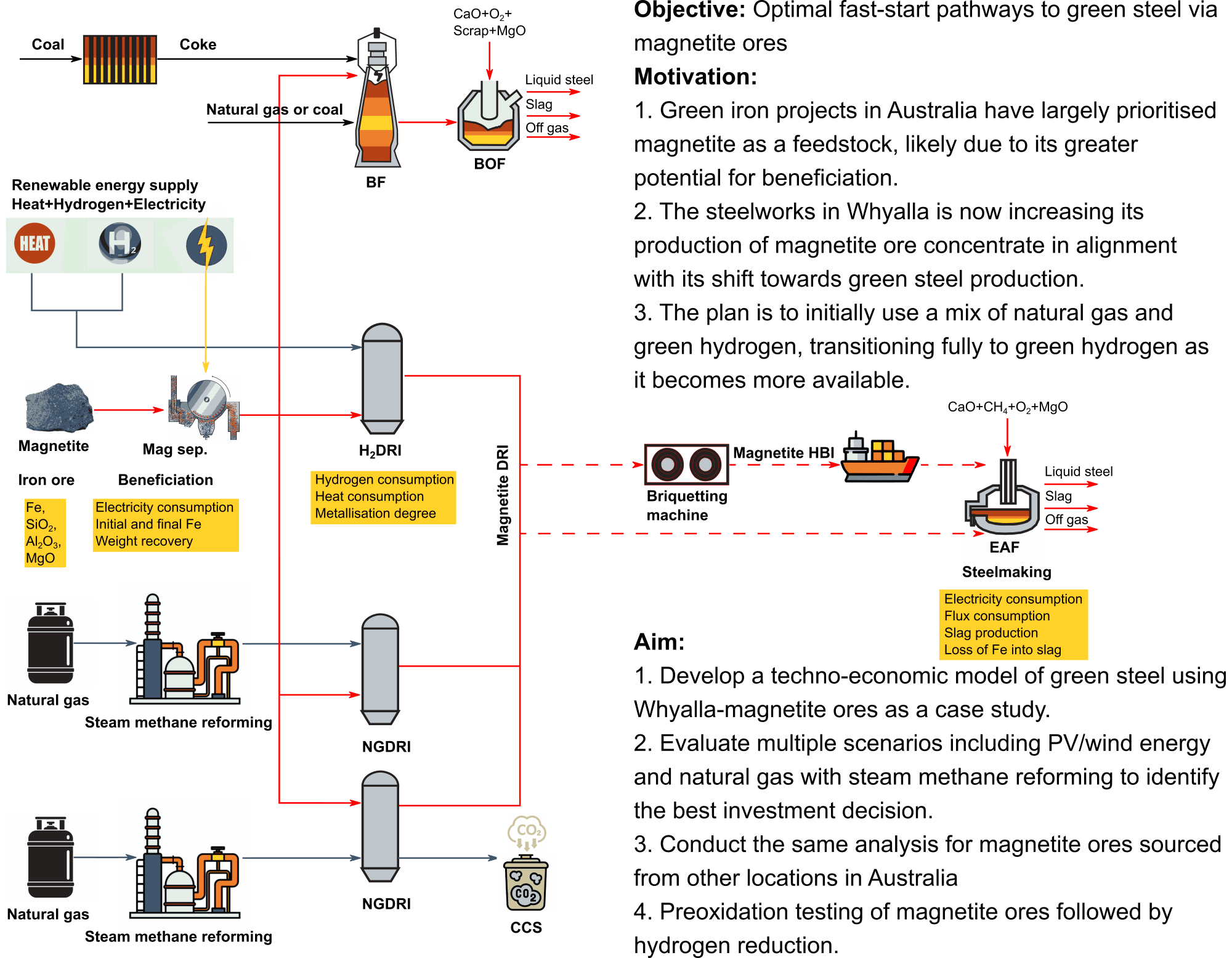

With their suitability for upgrading, Australia’s magnetite iron ores are well-suited for processing into green steel via hydrogen-based direct reduced iron (H₂DRI) and electric arc furnace (EAF) processing.

This project explores how Australia can leverage its magnetite resources to fast-track the development of a competitive, low-emissions steel industry. By developing a detailed technoeconomic model and conducting targeted testing, the project will help iron and steel producers understand the cost, infrastructure, potential revenue streams and policy settings required to scale up green steel production using magnetite.

Project Details

The project focuses on modelling and testing end-to-end green steel pathways based on magnetite ores, starting from beneficiation and moving through to H₂DRI and downstream processing. The model will quantify costs, emissions and technology options under a range of regional scenarios, beginning with Whyalla (South Australia) and extending to the Pilbara (Western Australia), Burnie (Tasmania) and Braemar (South Australia).

The research will adopt a phased strategy, using natural gas DRI (NGDRI) initially, then shifting to full hydrogen-based production. The project will characterise magnetite ores supplied by industry partners and compare end-to-end costs of magnetite-derived green iron and steel with costs using hematite-goethite ores.

While industry’s current preferred approach is magnetite-derived hematite pellets for shaft furnace H2DRI-EAF processing, the project will explore how pre-oxidation treatment of magnetite ores can enhance their reducibility behaviour in the downstream H2DRI process.

RP1.018 will also advance the understanding and application of key emerging technologies within HILT CRC – such as thermal comminution based on high heating fluxes and rates to upgrade ore quality and reduce crushing energy – to determine if and how these technologies can unlock new opportunities for scalable, cost-effective green magnetite-based steelmaking.

Project structure

HILT CRC Milestones

- 1.1 Producing green iron products from magnetite

Research Areas

- Decarbonise production of green iron products from magnetite ores

- Low-carbon pellet production

- Use hydrogen (or ammonia) for pellet induration of Australian ores

Planned Outcomes

- A comprehensive technoeconomic model for magnetite-based green steel production across key regions (Whyalla, Pilbara, Burnie, Braemar).

- Cost comparison of magnetite-derived green iron and steel versus that produced from hematite-goethite ores

- Levelised cost estimates for hot briquetted iron and final steel products.

- Scenarios that evaluate the transition from NGDRI to H₂DRI, including carbon capture and storage (CCS) and carbon pricing.

- Comprehensive data gathering of magnetite beneficiation, ore composition, renewable energy costs, cost/shipping rules for the HBI process, levelised cost of the final product for different locations, and carbon tax required for leapfrogging from natural gas to green ironmaking.

- Experimental data on ore pre-oxidation and associated hydrogen reduction behaviour.

- Comparative analysis with hematite/goethite-based steelmaking pathways.

Project Benefits

- Supports investment and policy planning: Provides industry and government with clear data to guide infrastructure investment, funding decisions and regulatory settings that support green steel production from magnetite.

- Supports regional development: Evaluates region-specific options, enabling tailored strategies for Whyalla, Pilbara, Burnie and Braemar, based on ore quality, energy availability and transport costs.

- Reduces transition risk: By modelling phased adoption from NGDRI to H₂DRI, the project helps de-risk early investment and prepares industry for long-term, hydrogen-only operations.

- Unlocks technology pathways: Assesses the potential of fluidised bed reduction, thermal comminution and thermal pre-oxidation to streamline processing and lower emissions.

- Informs CCS and carbon pricing strategies: Quantifies the policy levers – such as carbon tax levels – needed to make green steel cost-competitive, supporting advocacy for industry-wide decarbonisation.

Download the Project Summary

RP1.018 Optimal fast-start pathways to green steel via magnetite