Overview

Many industry processes – such as alumina refining and iron ore pelletising – depend on high-temperature heat, often generated from fossil fuels like natural gas. To meet net-zero targets, these industries need reliable and affordable low-emissions alternatives.

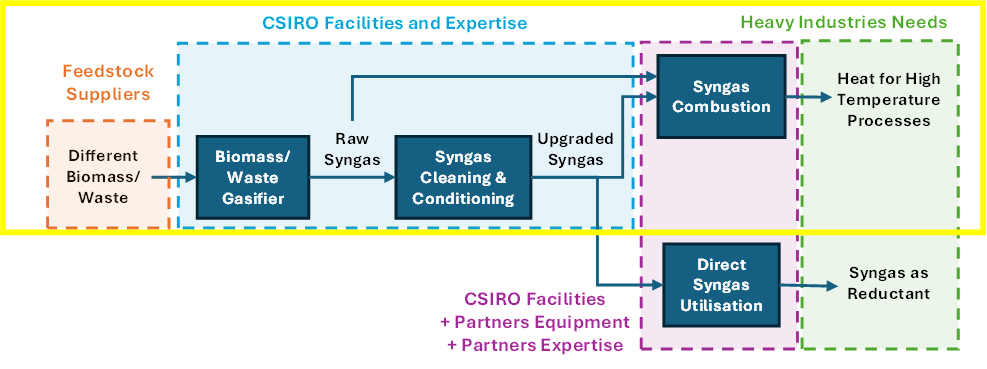

This project explores one promising pathway: using syngas derived from locally available biomass and waste as an alternative to natural gas. Syngas is produced by heating biomass/waste under specific conditions (a process known as gasification). By producing and using syngas in existing industrial equipment as a natural gas replacement (either partial or complete), heavy industry companies have an opportunity to reduce carbon emissions without needing to invest in entirely new infrastructure.

Project Details

This project focuses on demonstrating the potential of syngas derived from different Australian biomass and waste resources as a practical alternative to natural gas for high-temperature processes in heavy industry.

The project team will demonstrate and analyse the performance of a pilot-scale system, tailored for heavy industries, that combines a biomass gasifier with a syngas burner. This system will be tested with a range of local feedstocks – including agricultural waste, wood residues and engineered fuels like RDF – to assess fuel quality, combustion performance and emissions.

In addition to technical performance, the project will conduct a technoeconomic analysis to compare syngas with other low-carbon options such as green hydrogen and electrification. It will also collect the emissions data needed for engaging with regulators for environmental approvals, helping pave the way for commercial-scale applications.

To provide guidance on regulatory risks, policy alignment and community concerns, RP2.018 will also examine the regulatory and social dimensions of biomass use, including:

- mapping federal and state regulatory frameworks

- conducting a gap analysis of conflicting or unclear policies

- evaluating social-licence-to-operate considerations, such as workforce, environmental and economic concerns.

RP2.018 follows on from RP2.012 Opportunities for bioenergy in Australian heavy industry, which identified significant local availability of biomass and waste resources capable of supporting specific heavy industries to either fully or partially decarbonise their high-temperature processes.

This project also draws on the findings of RP2.010 Utilisation of refuse-derived fuel in industrial processes: understanding the value proposition, risks and supply chains, which investigated the potential of RDF and identified RDF-derived syngas as a cost-effective, low-carbon alternative fuel for decarbonising high-temperature processes in heavy industries. RP2.018 also addresses challenges regarding the consistency of feedstock supply and its effects on the gasification process.

Overview of pathways to use biomass/waste-derived syngas for heavy industries application.

HILT CRC Milestones

- 2.1 Integrating variable renewable energy sources into existing industrial processes

- 2.2 Technology to accommodate use of multiple energy sources

- 2.4 Blending of alternative low-carbon fuels for current industrial processes

- 2.5 Technologies to lower carbon emissions through synergistic production of industrial chemicals and fuel

Research Areas

- Blending of alternative low-carbon fuels for current high temperature processes

- Biomass, waste and other low-carbon fuels, including new combustion technologies

- New technologies for high-temperature heat

- Green heat for industry

Planned Outcomes

- A working pilot-scale system that demonstrates biomass/waste gasification and syngas combustion for

industrial use. - A comprehensive knowledge database detailing syngas quality and combustion performance using different feedstocks under different process conditions.

- Engineering insights into how syngas can be integrated into existing industrial systems.

- Technoeconomic comparisons of syngas with other low-carbon fuels.

- Emissions data to support regulatory approval and environmental permits.

Expected Benefits

- Lower emissions: Enables industries to partially or fully replace fossil fuels with renewable alternatives.

- Cost-effective transition: Potential to avoid the need for major infrastructure upgrades by retrofitting syngas systems into existing plants.

- Use of local resources: Taps into regional biomass and waste streams to create value and reduce transport emissions.

- Industry-specific solutions: Tailored approaches for companies such as HILT CRC Partners South32 and Grange Resources based on their energy needs.

- Roadmap to industry adoption: A pathway for further integration of high-temperature processes – such as alumina calcination – with gasification systems, can set the stage for industrial-scale demonstrations.

- Flexible fuel systems: Supports hybrid approaches, such as blending syngas with natural gas or hydrogen, for greater system resilience.

- Support for regulation and scale-up: Provides performance and emissions data to inform environmental approvals and future pilot projects.